For the operator, VarioTrack is easy to use. VarioTrack is safe and reliable: customers see ADR as a guarantee of safety.

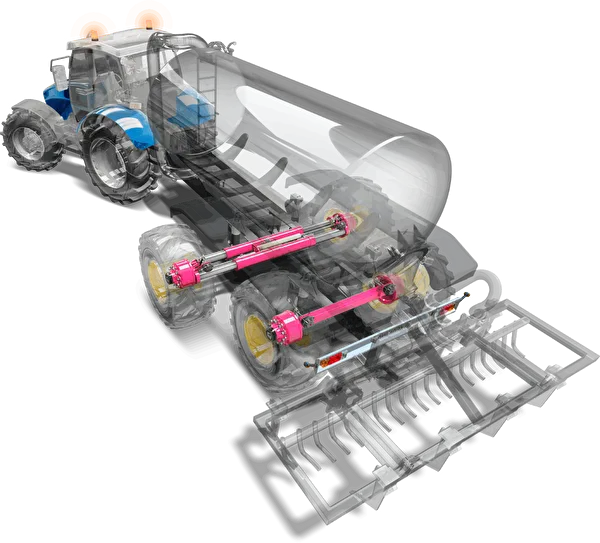

- Teknoax rotating assembly (hub/bearings) with a transportable load of up to 15T.

- Load bearing structure constructed using highly rigid elements with minimum clearance between them to bear the highest load capacities.

- Maneuvering cylinders with screwed pin fixing points to facilitate assembly, disassembly and maintenance.

- Special hydraulic valves to ensure user safety during movement.

- Hydraulic track variation actuated directly from inside the tractor.

- Sealing systems with low friction and a high load capacity ensuring virtually no maintenance over time.

- Chrome-plated sliding elements with low friction and high corrosion resistance over time.

- Availability of two braking assemblies: 4218E and 5218E.

- Provision for an integrated inflating / deflating system in the far spindle.