Following inspiring Eima 2022, the Adr group is diligently working on numerous innovations, promising some delightful surprises.

The extensive list of developments is set to invigorate the agricultural trailer sector, benefiting both manufacturers of agricultural machinery and end users alike. Stay tuned as these innovations may pave the way for revolutionary advancements in the industry.

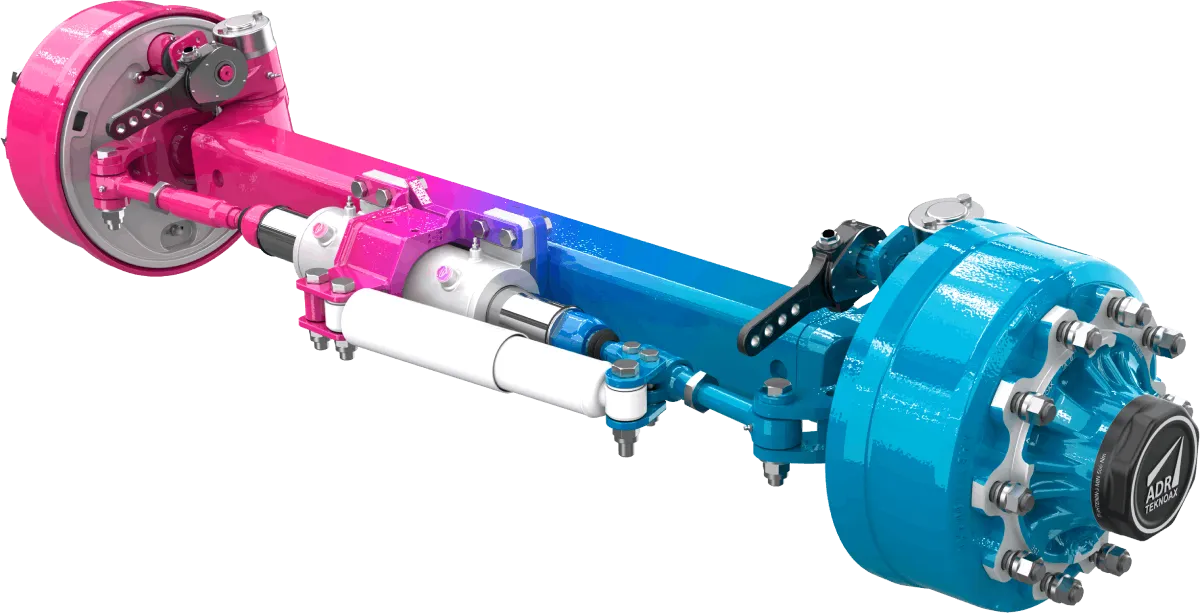

The ADR Group has consistently invested in extensive research and development, adapting its product offerings and technological advancements to meet the evolving market and agricultural needs. Recognizing the industry's demand, ADR was among the first to introduce hollow axles to the sector, a groundbreaking innovation that has since evolved into the current "TEKNOAX" axles. These axles can be seamlessly integrated into all ADR suspensions while supporting the most advanced electronic and digital systems.

Focused on research and development, ADR has made significant strides in these areas, dedicating continuous efforts even during the challenging lockdowns caused by the Covid-19 pandemic. Over the past two years, the ADR Research & Development Center has diligently restructured its operations with the specific goal of thoroughly reviewing, expanding, and enhancing the ADR product line.

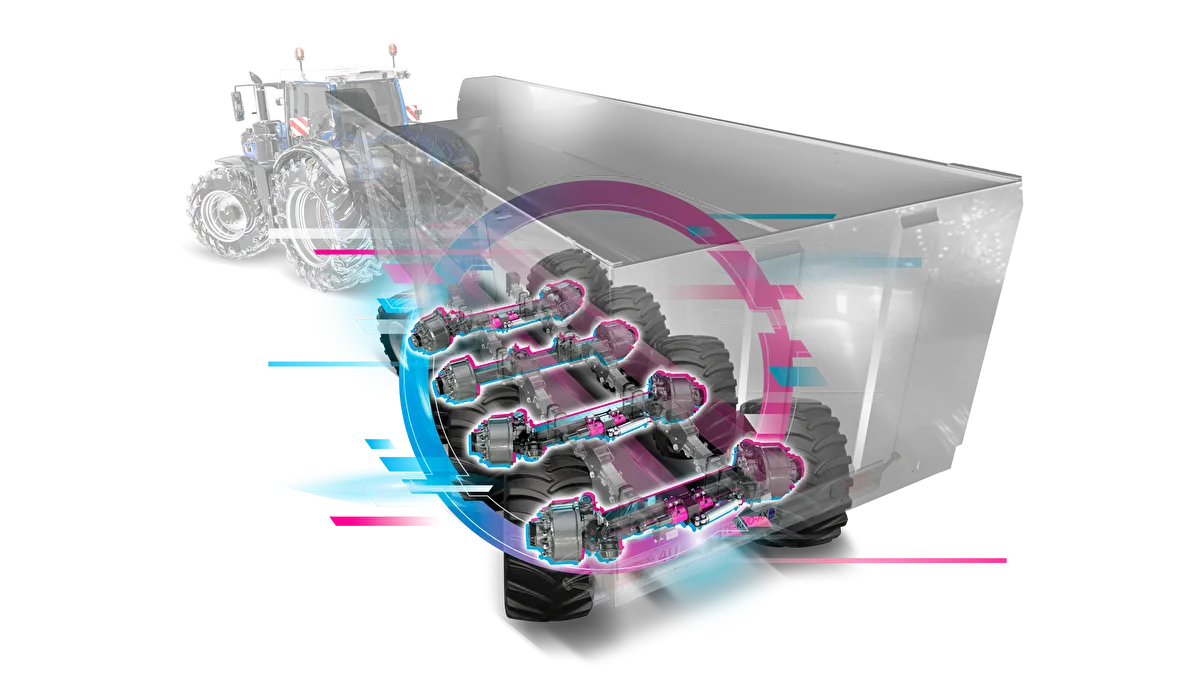

This tireless commitment has yielded new and exclusive functional and management technologies that was be unveiled at EIMA 2022. These innovations prioritize safety, maneuverability, and reduced maintenance needs for agricultural trailers. A complete revamp of the mechanical suspension family has been undertaken, with a specific focus on "low maintenance" design. The well-established "Ka" suspensions, available in capacities ranging from four to sixteen tons, will now be accompanied by new suspension groups capable of supporting capacities from four to 48 tons.

One notable addition is the robust "Tandem KB" suspension, already recognized and trusted in the market, which will be paired with an innovative braking system. This pairing will offer enhanced configuration possibilities for agricultural trailers with capacities of up to 12 tons per axle. ADR's commitment to reducing production costs is also evident through the extension of the "low maintenance" concept to all mechanical suspensions.

To further enhance efficiency and adaptability, ADR has launched the ADR/Ptg system. This system, compatible with ISOBUS, enables operators to adjust tire pressures while driving, ensuring optimal tire performance in terms of load capacity, traction, and minimal soil compaction. The system will also be incorporated into the new "Dual Function" axles, allowing for "self-steering" or "controlled" steering configurations without the need to replace any components. This feature benefits installers by streamlining inventory management and enabling faster response to customer requests.

Installers and end users alike will also benefit from operational upgrades introduced in the "RFID" APP, which traces the functional history of each individual axle. This facilitates predictive maintenance interventions, allowing for timely actions. The app also provides convenient access to spare parts codes and facilitates quick ordering for efficient delivery.

ADR Group's unwavering commitment to innovation and customer-centric solutions continues to drive advancements in the agricultural trailer sector, providing enhanced performance, safety, and maintenance capabilities.